Manufacturing advantages

Largest manufacturing base and strongest delivery capability in the world

Zhizao Base

Smart Factory 4.0

Fully automated production

Professional Skills Staff

As the first batch of certified national high-tech enterprises, it has built a complete R & D, manufacturing, sales and service system and independent production base, and is equipped with first-class R & D, production and experimental equipment in the two major manufacturing centers, leading the industry in modernization, scale and standardization, with a 40000 ㎡ LED display intelligent manufacturing base.

Relying on the strategic positioning of "industrial Internet finance", Helto introduces advanced production equipment, combines the latest application technology, builds smart factories, and realizes smart production; it leads the world in efficiency and cost, realizes industrial 4.0 upgrades, and manufacturing levels Connect with European and American countries. It has also recruited a large number of high-quality LED industry R & D elite teams and trained more than 500 professional and skilled employees who control each production chain.

Leading quality management system, strict quality control

To provide customers with satisfactory and assured quality products is the constant commitment of Herto Optoelectronics to every customer.

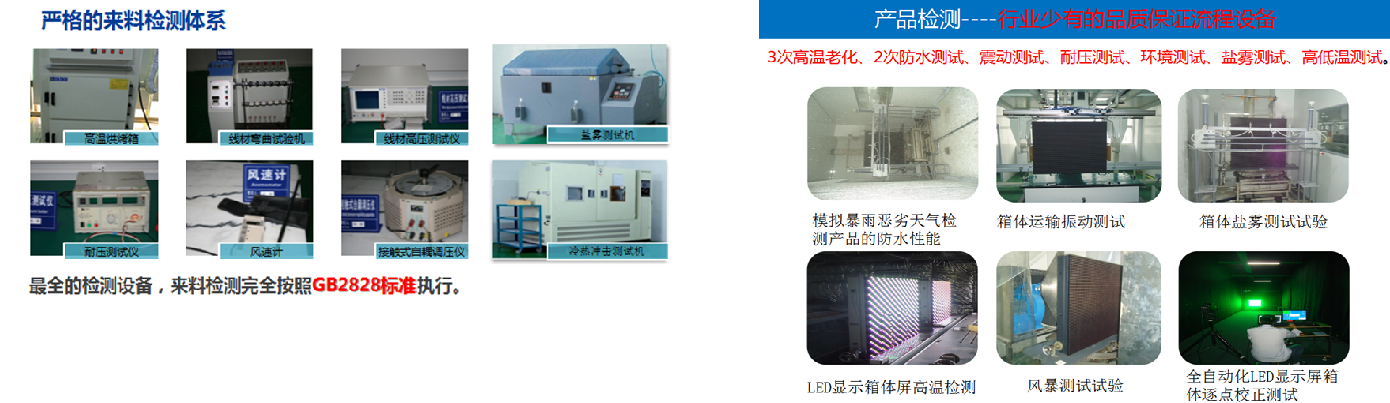

From the selection of raw materials to the production, processing and manufacturing of products, and the inspection and acceptance of finished products, Herto Optoelectronics strictly controls every pass. All raw materials are strictly tested and screened, and incoming materials are tested in full accordance with GB2828 standard. Automatic production equipment and testing equipment of first-line brands (Panasonic, Gree, etc.) at home and abroad have been introduced successively. The quality of raw materials is strictly guarded with the most complete testing equipment, and Hull Tuo's immortal brand is forged with core technology.